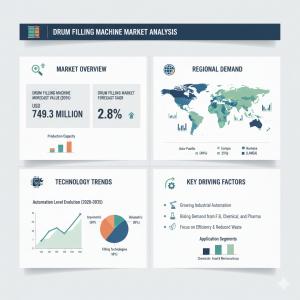

Drum Filling Machine Market Set to Hit USD 749.3 Mn by 2035 — Strong Momentum in APAC, Europe, USA & Saudi Arabia

The drum filling machine market is expanding steadily, driven by automation, industrial modernization, and safety-focused innovation.

NEWARK, DE, UNITED STATES, November 7, 2025 /EINPresswire.com/ -- The global Drum Filling Machine Market is valued at USD 568.5 million in 2025 and is projected to reach USD 749.3 million by 2035, registering a 2.8% CAGR over the forecast period. Growth is fueled by rising demand from the chemical and petrochemical sectors, increasing automation across industries, and tighter regulations around safe handling and filling of bulk liquids.

Context

The upward trajectory of the drum filling machine sector reflects growing strategic priorities among manufacturers for operational efficiency, safety compliance, and modular flexibility. Industries such as chemicals, food & beverage, lubrication, and paints are increasingly investing in customizable drum-handling and filling equipment to meet stringent standards while optimizing throughput. Drum filling machines offer a pathway to precision dosing, reduced waste, and faster change-overs — providing both margin resilience and regulatory reassurance for modern production facilities.

Fast Facts

• Market Value (2025): USD 568.5 million

• Market Forecast (2035): USD 749.3 million

• CAGR (2025–2035): 2.8%

• Leading End-Use Sectors: Chemicals, food & beverages, and pharmaceuticals

• Key Growth Regions: India (~3.0% CAGR to 2034), China (~2.9% CAGR to 2034)

To access the complete data tables and in-depth insights, request a sample report here: https://www.futuremarketinsights.com/reports/sample/rep-gb-19574

What’s Winning, and Why

Drum filling machines are gaining traction because they address multiple operational pain-points simultaneously. Manufacturers are upgrading to solutions that deliver accurate, high-volume filling with repeatability, minimal human intervention, and strong hygiene or safety credentials. In chemical and petrochemical segments — where handling high volumes of bulk liquids is critical — the demand for reliable drum filling systems is robust. Institutional buyers favor suppliers who offer modular, scalable systems that integrate easily into existing lines and meet evolving regulatory demands around emissions, spills, and waste.

Where to Play: Channels & Regions

The drum filling machine market is best approached through a mix of direct OEM sales and system-integration partnerships, particularly in regions where manufacturing investments are growing. Key regional insights include:

• India: CAGR of ~3.0% through 2034, boosted by SMEs and export-oriented manufacturing adopting drum filling solutions.

• China: CAGR of ~2.9% through 2034, with strong emphasis on sustainability, automation, and local equipment sourcing.

• USA: Steady demand driven by automation and regulations across chemical, lubricants, and food industries.

• Japan: CAGR ~2.8% to 2034, with growth supported by pharmaceutical and specialty chemical segments.

What Teams Should Do Next

R&D

Focus on modular designs and smart features — such as IoT connectivity, predictive maintenance, and flexible dosing stations — to deliver value above basic filling.

Develop variants tailored for hazardous materials, corrosive substances, and food-grade applications, emphasizing safety, accuracy, and ease of cleaning.

Marketing & Sales

Position offerings on the twin pillars of precision/flexibility and regulatory/safety readiness.

Target end-users in chemicals, lubricants, and export-oriented food & beverage facilities modernizing packaging and filling lines.

Use case studies emphasizing reduced downtime, improved yield, and compliance gains.

Regulatory & Quality

Ensure machines meet global standards for hygiene (food/pharma), hazardous-material handling, and operator safety.

Consult with customers on compliance and best practices for drum-based filling operations, including maintenance programs and line integration.

Sourcing

Secure reliable components for pumps, sensors, and automation modules — given the importance of uptime and precision in drum filling applications.

Identify regional service/support partners globally, since after-sales and maintenance reliability are cited drivers of repeat purchases.

Three Quick Plays This Quarter

• Secure a pilot project with a chemical manufacturer in Asia-Pacific to demonstrate modular drum-filling capability and ROI.

• Launch a co-branded marketing campaign with a lubricant/paint OEM emphasizing improved throughput and compliance.

• Develop an add-on smart-sensor package that enables predictive maintenance and connect it with the machine’s control interface for faster alerts and reduced downtime.

The Take

Drum filling machines are transforming filling lines in industries that handle bulk liquids and semi-liquids — from chemicals and paints to food ingredients and pharmaceuticals. Investment in more precise, efficient, and safer drum-handling systems strengthens production flexibility, reduces risk, and helps future-proof operations against sustainability and regulatory pressure. Manufacturers deploying these solutions can position themselves for operational advantage, higher throughput, and improved client trust.

Full Market Report Available for Delivery. For Purchase or Customization, Please Request Here: https://www.futuremarketinsights.com/checkout/19574

Media Line

For analyst briefings or custom cuts by machine type, capacity, end-use sector, or region, contact Future Market Insights.

Competitive Landscape

The market is moderately fragmented, with established machine suppliers and regional specialists. Key firms include Haver & Boecker, AiCROV, PACK’R, SIEHE Group, PESTOPACK, Palamatic Process, Specialty Equipment Corporation, Apacks, Seppa Solutions, and PASE Group.

Key Developments

• 2024: Enhanced modular drum-filling solutions introduced with weigh-scale integration and fast change-over features.

• 2023: Multiple manufacturers rolled out versions compliant for food-grade and pharma-grade drums, emphasizing easy-clean design and sanitation.

Closing Note

As chemical manufacturers, food & beverage processors, pharmaceutical firms, and specialty industrial producers accelerate modernization and operational flexibility, drum filling machines are an essential investment. By embracing automation, modularity, and safety-compliance, organizations position themselves not just for line-efficiency gains but for broader competitive resilience in evolving manufacturing landscapes.

Explore More Related Studies Published by FMI Research:

Breathable Lidding Film Packaging Market: https://www.futuremarketinsights.com/reports/breathable-lidding-film-packaging-market

Corrugated Wraps Market: https://www.futuremarketinsights.com/reports/corrugated-wraps-market

Child-resistant Containers Market: https://www.futuremarketinsights.com/reports/child-resistant-containers-market

Wheeled Insulated Cooler Market: https://www.futuremarketinsights.com/reports/wheeled-insulated-cooler-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Why FMI: https://www.futuremarketinsights.com/why-fmi

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

rahul.singh@futuremarketinsights.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.